RoboVision

.NET APP’s by koller robot solutions

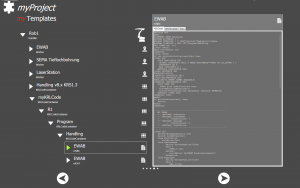

RoboVision.Designer

With rv.designer KUKA KRL-codes are easily generated.

- Define your machine(s)

- Create positions in the surrounding area of your machine(s)

- Add functions to the positions

- Ready – now you can generate the KRL-code

rv.Designer Tour ...

RoboVision.Schedule

‘rv.Schedule’ generates your product flow. Make use of rv.Designer generated positions in order to define your product schedule for single production steps. Those generated schedules can provide a KRL-code in order to navigate robot processes, also generate an SPS programme to allow the superordinate control to take over the sequence control or the rv.production takes over the control as master computer.

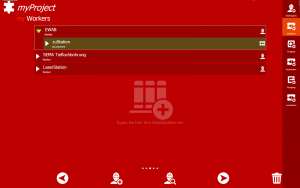

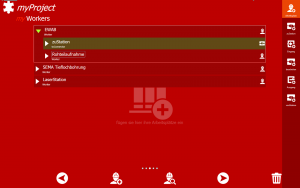

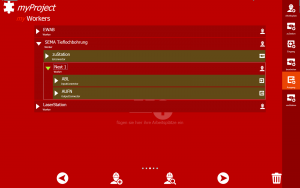

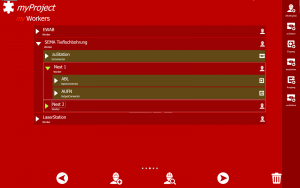

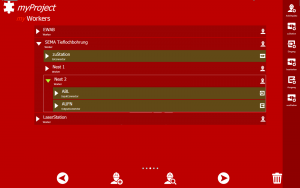

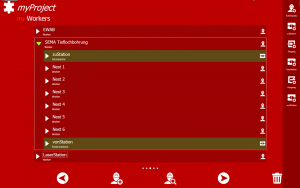

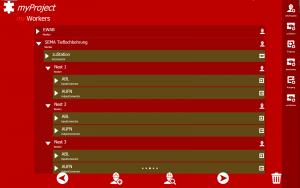

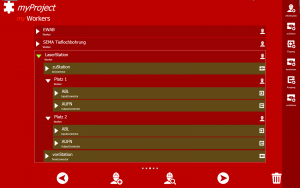

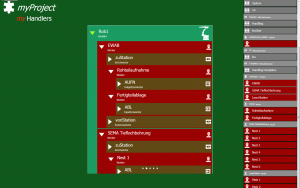

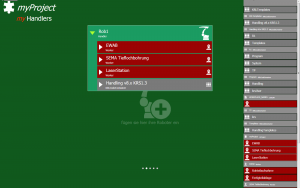

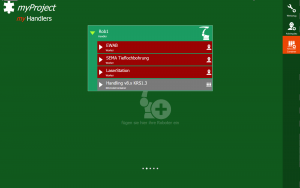

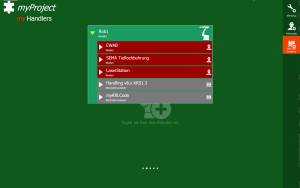

RoboVision.HMI

Rv.HMI has already been computer-optimized for Windows10 and multi-touch and is available as a tablet version. The communication with the robot runs via Ethernet. XML (alternatively OPC or customizing to the interface available). Initially, with rv.HMI we have succeeded in displaying sole functions and elements which are being processed at the specific moment of performance. The navigation on the functions of the plant is self-descriptive. Its interface was inspired by well-developed screens of modern smartphones and tablets.

RoboVision.Messenger

The rv.messenger filters from the RoboVision-controlled plant vast quantities of data, information, status, phases and events, especially those which you are interested in, and forwards them directly to your devices (PC, tablet, smartphone, printer,..).

For example, it is possible to configure your rv.Messenger so that you will be informed as soon as your plant counts 10 manufacturing cycles (shortage of material) left before end.

Ports

rv.Designer, rv.Schedule, rv.HMI und rv.Messenger access the same data pool and are perfectly attuned to one another.